Healthcare Technology Company Case Study: Wheels of Innovation: Co-Developing a Purpose-Built Medical Cart for AI-Enabled Remote Monitoring

By First Products on Jan 6th 2026

It’s not unusual for the team at First Products to have a senior-level executive from a healthcare organization visit us at HIMSS or other events and ask, “Can you create a mobile cart solution to support our complex technology?” Each visitor may have a variety of devices to integrate—or just one—that needs to work seamlessly with the cart. And First’s response?

“We typically are able to say yes to everything the visitor is asking, understanding their need for a hardware product to suit their IT solution with the same innovation they are bringing to their market,” said Paul Smith, First Products’ CEO and third-generation company owner. “We’ve created a business model where clients can receive a customized product quickly, efficiently, and cost-effectively—whether it does just two things or many. We take as much time as the client needs to get it right.”

One such meeting took place in 2022, when a prominent healthcare technology solution company CEO met Paul Smith at a HIMSS event. The company had launched a solution designed to improve the lives of clinicians and patients. While it addressed current care delivery, it also prepared organizations for future advancements in clinical workflows and patient care.

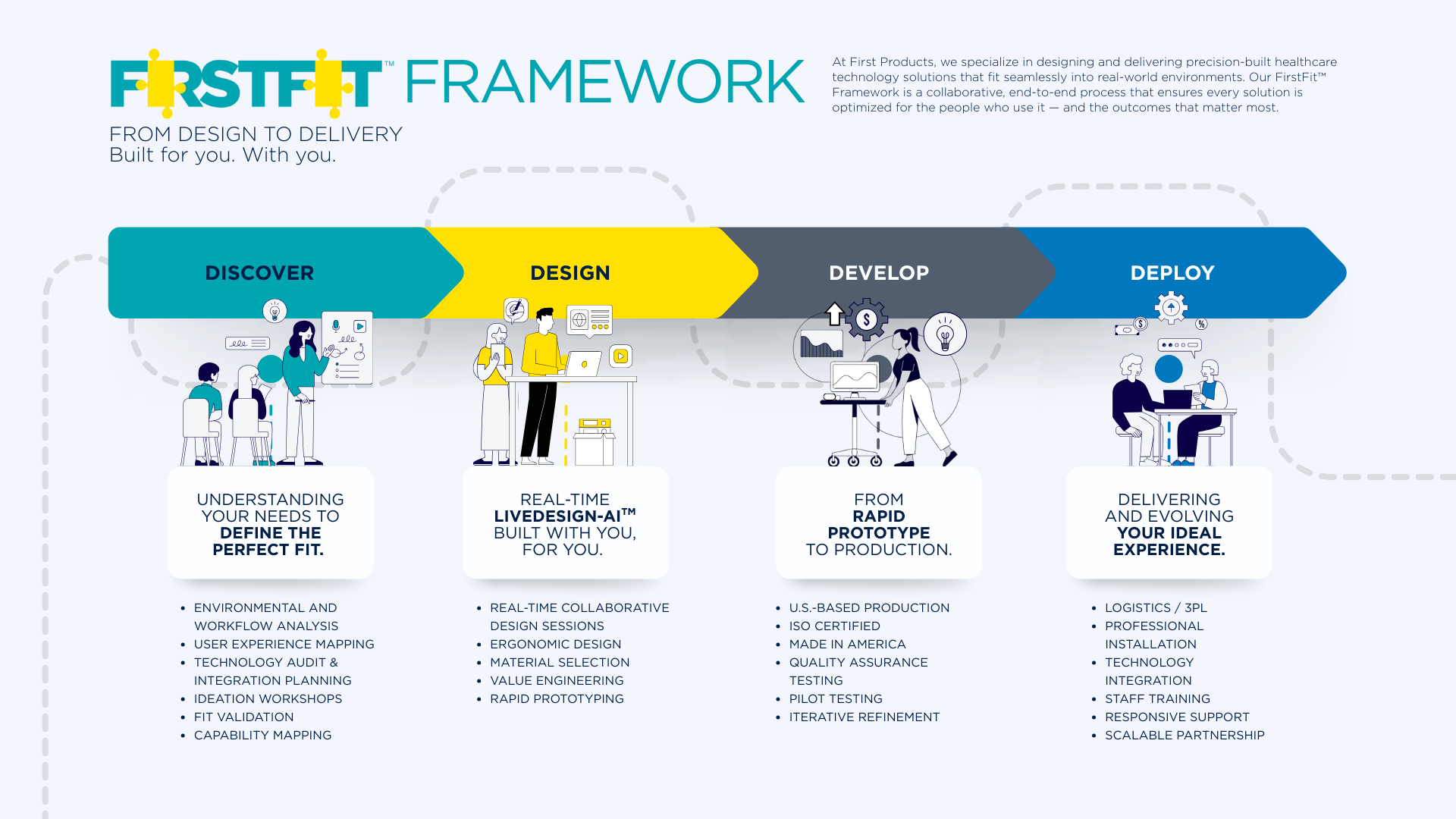

However, there were issues with their existing medical cart supplier. The CEO wanted to learn more about First’s Perfect Fit process and its innovation strategy.

The Challenge

The CEO expressed the need for a technically complex solution requiring deep electronic integration. Multiple device and mounting applications needed to work together—such as multi-sensor networks, real-time location systems, voice-activated services, video conferencing, and more—across demanding healthcare environments.

The company understood the iterative nature of the Perfect Fit process and sought a manufacturing partner who was solution-driven, collaborative, and capable of delivering fully integrated carts with strong logistical support.

“We understand when customers come looking for a different manufacturing model. It’s easy to get bogged down in prototyping and feel like time is being lost,” said Paul. “We’ve created a different approach—fast-turnaround evaluation units where the client is intrinsically involved from day one as we build the solution together.”

Working Together for a First Perfect Fit

The Perfect Fit process begins by gathering component specifications. The healthcare technology team met with First to determine how the technology would integrate, where the carts would be deployed, and what challenges needed to be addressed.

This stage aligns with First’s proactive OEM component lifecycle monitoring, helping future-proof the solution while supporting logistics such as inventory-based shipping and specific delivery requirements.

From there, First’s design and engineering team created initial concepts for review. This collaborative exchange allowed both teams to uncover every feature the client ultimately required.

“This is the fun part—everyone pitching in to move the process forward. We can adapt to the client’s timing, even making real-time design changes on screen or inviting them in to work alongside us,” said Paul.

It’s All in the Design

The healthcare technology company required a solution capable of supporting demanding mobile workflows. Key requirements included:

- Mounting a PTZ camera and all-in-one computer

- Securing a speakerphone and supporting electronics

- Advanced cable management

- Rugged steel and aluminum construction

- Engineering to withstand medical surge environments

- High-level component security

The client emphasized the need for an ultra-rugged solution—secure enough to handle heavy public interaction, especially in remote monitoring environments.

Designing the Solution from the Ground Up

First Products engineered every aspect of the patient monitoring cart, including molded plastic components, ergonomic structure, aesthetics, and advanced cable management—one of First’s key differentiators.

“We designed it so you don’t see the cables at all,” said John Henry, Senior Engineer at First Products. “Everything is safely organized and secured to prevent damage. Not all manufacturers offer that.”

Once approved, First delivered fully functional evaluation units for pilot testing—at a much faster turnaround than the client had experienced previously.

“It’s important clients can implement the solution before full rollout. This evaluation phase allows refinements before final deployment and ensures our Perfect Fit stamp of approval,” said Paul.

Fully Integrated, Fully Functional, and Future-Proofed

Because First works directly with component manufacturers, the evaluation phase validated the fully integrated solution. When production scaled to hundreds of units, each cart shipped fully configured with installed hardware, software, and accessories.

First also addressed future-proofing by monitoring OEM component lifecycles and managing design changes proactively. White-glove delivery ensured carts arrived directly to deployment sites—unpacked, damage-free, and ready to use. End users simply plugged them in and connected to Wi-Fi.

“Once we understood what the client wanted, we pivoted quickly to deliver a solution perfectly aligned with their growth,” said Paul.

Technology & Integration Partners: Supporting Digital Transformation

First Products has taken a deeply collaborative approach with this healthcare technology partner—providing one-on-one support, logistics coordination, inventory storage, and freight management.

“Our mission is to help clients execute what differentiates them so they can win in the market. When they grow, we grow,” said Paul.

First Products remains committed to a personal, trust-based approach when delivering premium mounting solutions for demanding healthcare environments—upholding decades of quality while continually refining innovation.