Smart Prototyping: How OEMs Benefit from Collaborative Cart Systems Design & Development

By First Products on Sep 3rd 2025

Prototyping is a pivotal point in an OEM project, especially when a delay can cost months—and millions.

With a smarter prototyping phase that embraces collaborative design and development, First Products is helping OEMs transform complexity into speed and competitive advantage.

Prototyping is a critical aspect of First’s Product medical cart customization process. We know that for any prospective OEM client, this can be a make-or-break phase. With so much riding on each project, how the prototyping process is executed reveals not only a vendor’s full capability, but it also speaks to the vendor's transparency, agility, and overall responsiveness. OEM clients face rigorous regulatory scrutiny when introducing new and complex medical equipment and devices. They require high confidence that their solutions will perform as expected before major rollouts. It’s in the prototype phase where their premise is proven.

The prototyping process can reveal many things about a manufacturer’s ability to fulfill an OEM’s brand promise. From their perspective, OEM clients will learn in this phase:

- Can the manufacturer deliver functional prototypes realistically representative of their vision? This means taking into consideration final production concerns, such as tolerances or scalability, and demonstrates production readiness even in early samples.

- Does the manufacturer offer a collaborative design and engineering environment with clear communication, design, and problem-solving insight?

- Has the manufacturer implemented iterative feedback in an accurate way, without pushback or delays?

- Does the prototype reflect the manufacturer’s engineering quality, documentation, and attention to detail?

- Has the Manufacturer made it possible to assess early factors like fit for the team and functionality testing before final development?

Many of these expectations, if not met, serve as red flags, such as missed timelines, poor communication, overpromising, or subpar design and engineering practices. For instance, if the vendor doesn’t offer DFM (Design for Manufacturability) insights early enough, or is unrealistic about material constraints. These missteps erode trust and can reveal a mismatch with the Manufacturer’s production capabilities and the OEM client’s expectations.

The Problem OEMs Need to Solve

Ultimately, the OEM clients’ problem is to find a manufacturing partner to produce a cart system that supports the technology they need to deliver, when they need to deliver it, and where they need to deliver it in the final deployment phase. A first-rate prototype and prototype process can support this challenge.

Where OEM clients may encounter traditional prototyping issues is when they feel like a number in a project queue, with their project scheduled to meet the manufacturer’s agenda rather than their own. Or, if the process adds complexity, unplanned costs, or unnecessary risk to their scope. In other words, OEM clients want:

- A vendor that aligns with unique product specs, brand requirements, or integration needs.

- A vendor that understands the OEM's product lifecycle, regulatory concerns, and logistical requirements.

- A vendor that optimizes prototyping processes for cost-effectiveness at each prototyping stage

- A vendor that understands the OEM's strong brand requirements to launch a high-quality and well-designed medical solution that contributes to better patient care and outcomes.

Our Solution: A New Paradigm on Traditional Prototyping

First’s Prototyping Phase is designed to reduce redundancy, eliminate downtime, and hold to the scoped costs. We recognize that OEM clients set the pace for any project, and we have adapted our prototyping process to eliminate the inefficiencies and waste that traditional prototyping may entail. We accomplish this in the following ways:

- Although we will design from the ground up, our modular cart systems often prove to be the perfect foundation for a strategic customization approach without extra design or engineering required.

- Clients set the timelines, and we provide accessibility: either remote or in person, their teams come to us or we go to them. Through this real-time process, clients are involved in each step, advancing or pausing as they deem, giving them more control over their development schedules.

- This collaborative approach ensures that what is produced for the prototype is representative of their vision. The unit or units can be integrated with their technology and piloted in actual workflows, per the OEM customer’s requirements, for proof of concept.

- First doesn’t require high minimum requirement runs to create a prototype. While we recognize that sometimes just one is needed, we can also accommodate multiple stakeholders if many are necessary in order to assess the prototypes at different locations.

- Through iterative prototyping and testing, vendors can help OEMs refine device design, improve functionality, and ensure the final product meets stringent quality and safety standards.

- All prototypes are produced in our Lockport, New York, where the designers and engineers are at work. This eliminates time delays and added costs that overseas prototyping services introduce into the scope. We deliver the cart system to OEM clients to integrate their technology, or we can integrate it for them at their request. The personal touch is evident in every aspect of the process, creating that perfect fit that is our hallmark.

- We manage all the logistics of getting the prototypes to the correct review teams, testing the final rollout procedures in advance for smoother deployments at launch.

The team's experience and agility minimize downtime between iterations, allowing out-of-the-box thinking and insights on the fly, which can be accepted or rejected instantly, and keep the project moving forward. Our goal is the client's goal: to prove the workflow adaptability of the OEM solution at the prototype phase.

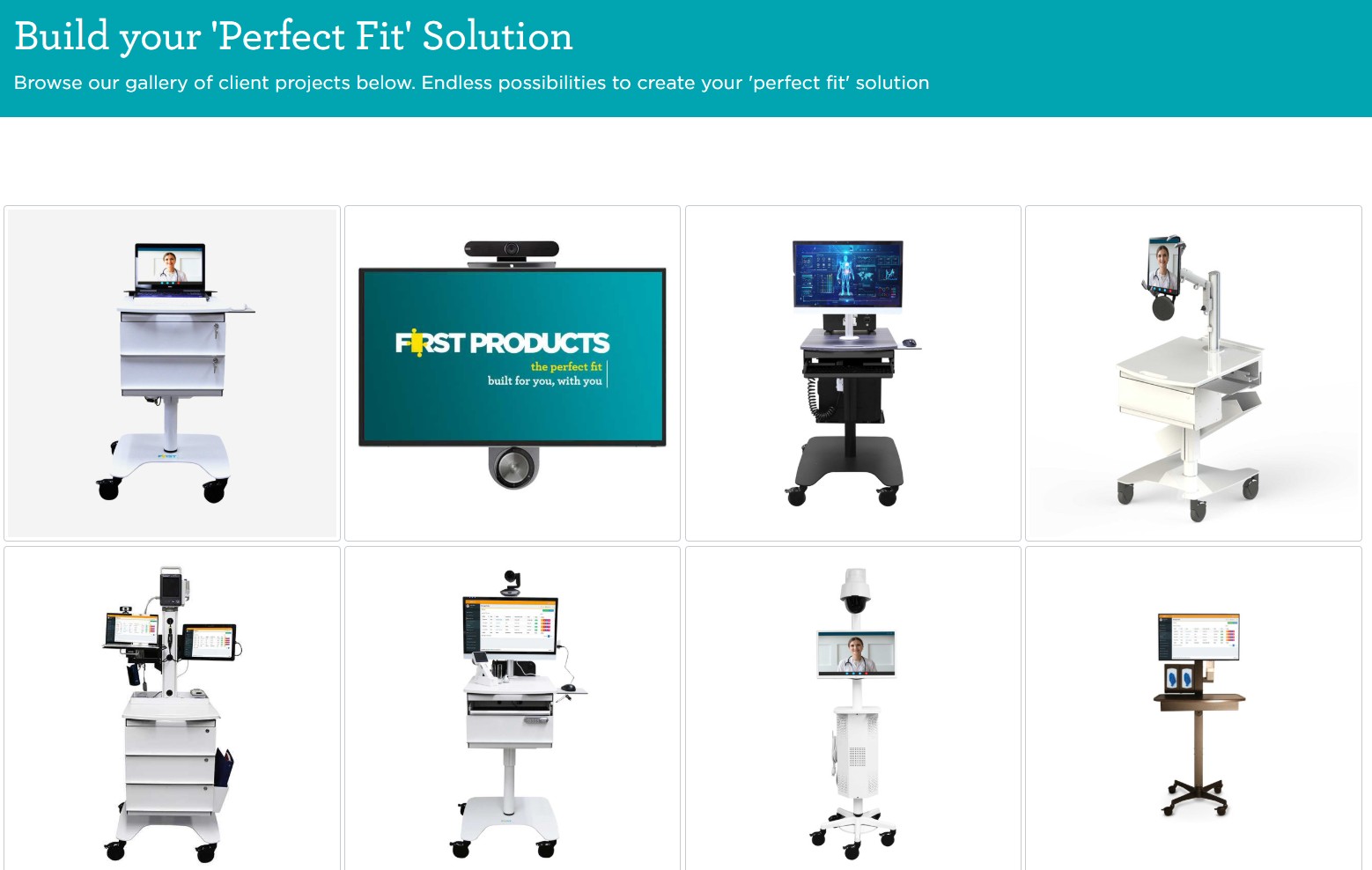

See our gallery of successful OEM projects.

Building OEM Trust Is Our Priority and Our Promise

The hoops that an OEM medical solution goes through to get approved is quite complex. Trust is established when manufacturers adhere to the disciplines inherent in a vendor with proven expertise and a strong track record in medical cart system prototyping. This includes transparency about pricing, scope, roadmap compatibility, and OEM intellectual property protections. It also involves designing solutions that are built to last, supporting long-term maintainability.

By carefully selecting and collaborating with vendors who meet these expectations, OEMs can navigate the complexities of medical device development and bring their life-changing innovations to patients efficiently and responsibly.

At First Products, our FirstFit™ Framework is more than a project workflow — it's a partnership model that prioritizes client performance and needs. From initial discovery to full deployment, the First team is passionate about delivering on OEM brand promises and introducing new devices to the market in a timely fashion.

We’re more than a medical cart vendor; rather, we're a manufacturing partner with a shared vision to transform healthcare outcomes.